|

How Electricity

works

ELECTRICAL

In the professional world of electrical wire installations the wiring

is installed neat and orderly manor. If you install the electrical wiring in

straight lines with 90 degree bends you robot will be great to look at and be

easy to work on. Take time to number or mark all of the wires at both ends.

Label The relays and PWM's to what motors they go to. If you install it sloppy,

cutting corners and no ties it will look bad and will be hard to trace problems

down. Take pride in your work and you will be happy to show others what you have

accomplished.

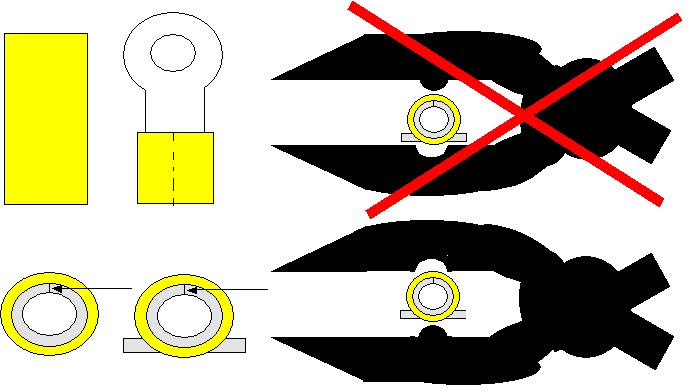

The most important part or your robot is your electrical connection. Be

extremely careful of how you crimp your wire connectors. You MUST use a proper

crimp tool (Sta-Kon type tool is the best) Inspect the wire connector and you

will see a seam ( arrow below). This seam MUST be opposite of the knob of the

crimp tool to make a proper crimp. The connector should fit down into the valley

of the tool a the wire should be stripped to proper length and crimped firmly.

The most important part or your robot is your electrical connection. Be

extremely careful of how you crimp your wire connectors. You MUST use a proper

crimp tool (Sta-Kon type tool is the best) Inspect the wire connector and you

will see a seam ( arrow below). This seam MUST be opposite of the knob of the

crimp tool to make a proper crimp. The connector should fit down into the valley

of the tool a the wire should be stripped to proper length and crimped firmly.

Proper Crimp Tool is on the left, the right is what most people use and it does

not do a good job for crimping wire connectors. It does a great job of cutting

screws but I have seen many connections come loose with that tool.

______________________________________________________

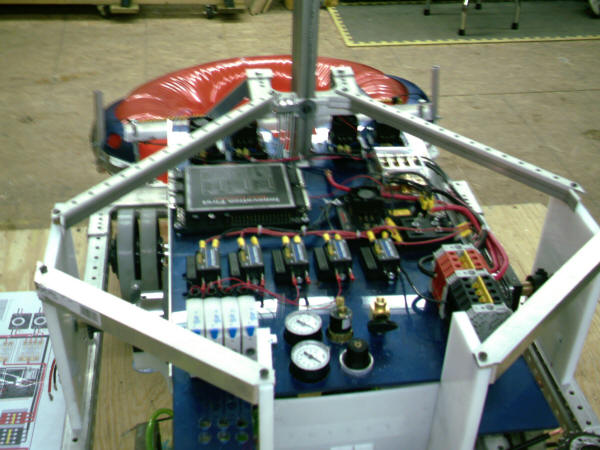

Want your electrical to look great, use solid wire. You can bend

perfect 90's and it won't bend back. This is only used from the fuse block to

the PWM's and relay's. Install quick disconnect wire connectors at

the motors for easy motor replacement. Make a bracket wire trough at 2 - 3

inches above the wiring board for the control wires to run separate from the

motor wires. It's like having a wire rack. Save copies of the PWM's and spike relays in your drawing programs,

and when its time to lay out the electrical it won't take long at all to set up

your board. Plus you can move it around until it fits.

Above is exactly the same lay out of our 2007 robot electrical below.

_________________________________________________________________

In 2008 we installed the relays and PWM's on one side and ran the wires on

the other side of the electrical board. This made it easier to work on and keep

tract of the wires. Below is a picture of our 2008 robot (the picture is

distorted to make it fit on the page) with the left, back and right side of the

robot.

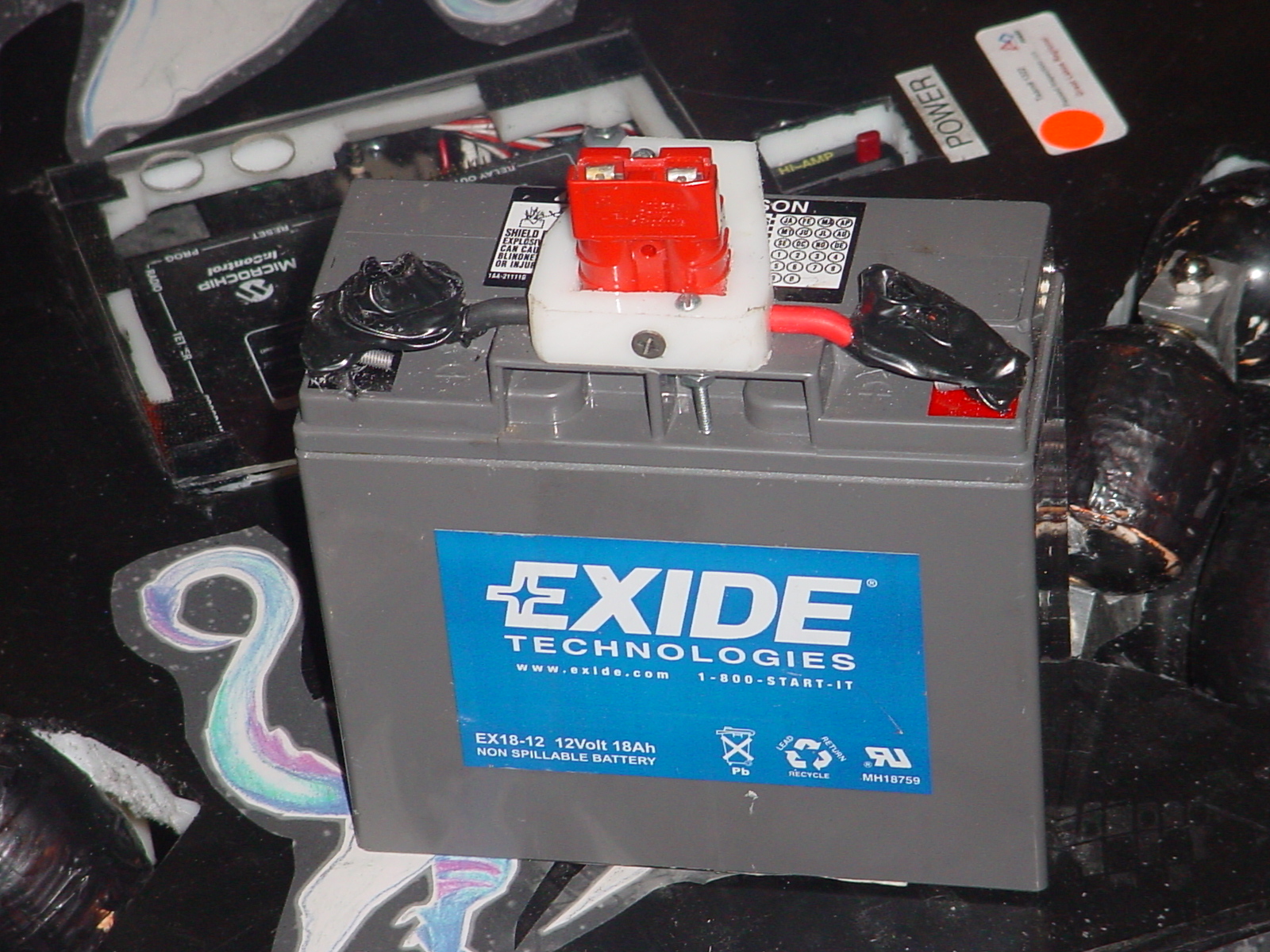

Some thing we do with the battery in make it a modular plug in. All of

our batteries are the same. When it is time to change a battery we just

pull it out and plug in another.

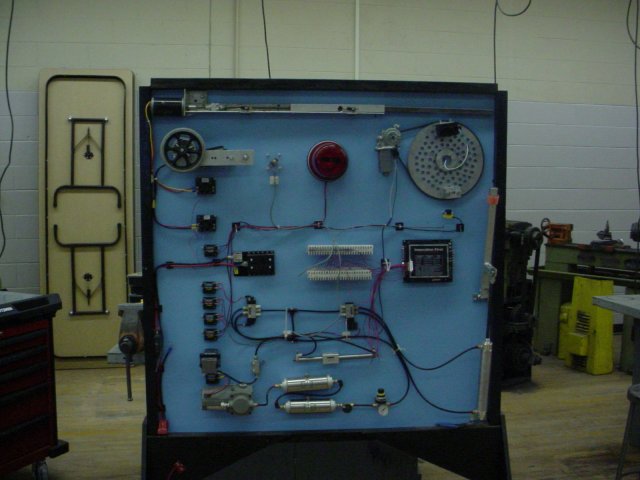

Build a board on wheels with the items from older kit of parts used to help show new students

how

all the items in the kit of parts work. It also can be used to test programming and

parts. The reverse side can be a erase marker board.

Pneumatics, electric, sensors and controllers can be shown on the board.

|